rockwell hardness test differ from the brinell test|brinell hardness test calculation : makers While several variants of hardness testing methods are available to hardness . WEBUm mês após a prisão do streamer Raulino “RaulZito” de Oliveira Maciel, a Twitch baniu o usuário da plataforma. Ele foi preso após ser acusado de .

{plog:ftitle_list}

Baixar PicsArt Photo Studio Android Grátis. PicsArt Photo St.

Brinell test is better than the Rockwell hardness test because it can measure the hardness of though material which is not measurable by another test like Rockwell. Brinell test measures the hardness of objects with coarse and refought surfaces and provides accurate .While several variants of hardness testing methods are available to hardness .

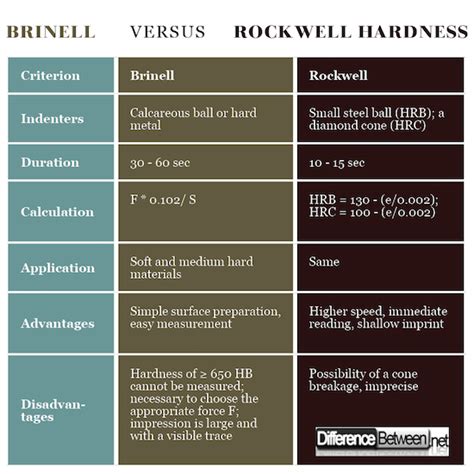

What is The Difference Between The Brinell and Rockwell Hardness Tests? While the two tests have similarities, there are several important differences. Both test methods are suitable for the testing of soft and medium hard materials .Rockwell’s test is shorter (10 – 15sec). Calculation of Brinell and Rockwell Hardness. Brinell’s Hardness (HB) is the ratio of the applied force F (N) and the surface of the fingerprint S (mm .Difference between, Brinell,Rockwell and Vickers Hardness Test. What is Hardness? Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also .

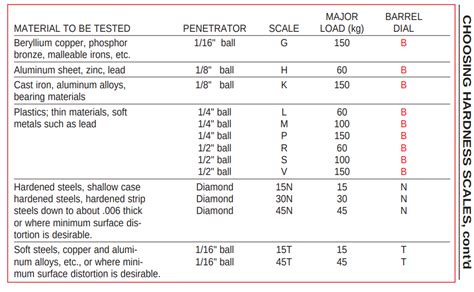

While several variants of hardness testing methods are available to hardness inspectors in the industry today, the Rockwell, Brinell, and Vickers hardness tests remain the . Both the Brinell and Rockwell hardness tests are valuable tools for assessing the hardness of materials. The choice between them depends on the specific material being tested, the required precision, and the testing .

The Brinell hardness test uses a spherical indenter, while the Rockwell hardness test uses either a diamond cone or steel ball indenter. Another difference is the amount of force applied to the surface of the material.

Rockwell Hardness (HR): Suitable for materials with high surface hardness, such as those treated with heat. Uses different scales based on the indenter and load: HRA: Diamond cone, 60 kg load, for extremely hard .Brinell hardness uses a ball or sphere indenter to measure the indentation depth, while Rockwell hardness uses either a diamond cone or a steel ball indenter and measures the depth of penetration and the residual depth after a . The Brinell test uses a hardened steel ball, while the Rockwell test uses either a diamond cone or a hardened steel ball. The choice of indenter depends on the material being .

ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in .

Knowing the best-suited hardness test of the three, Rockwell, Brinell, and Vickers, for your hardness test will require that you understand the determining criteria for employing any hardness test. This article aims to distinguish these methods and help you find the most suitable one for your testing situation.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find . Rockwell Hardness Test . The Rockwell hardness test, developed by Stanley P. Rockwell, is another widely used method for measuring hardness. It involves applying a minor initial load, followed by a major load, and then measuring the depth of penetration. The hardness value is determined based on the difference in penetration depth under the two .Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y axis) of the indentation are measured, and the hardness value . Test Cycle for Depth Difference Methods 1. The preload is applied to the sample and held for a specific time. For Rockwell methods the .

Home Articles Materials Hardness Testing of Metals: Rockwell, Brinell, Vickers, Knoop, and Leeb Tests. 29 August 2024. 1 . 0. . Below is a quick reference chart comparing the different hardness test methods in terms of suitable materials, advantages and disadvantages, applications, load range, indentation type and applicable standards. .

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload . What is Rockwell Hardness? Similar to Brinell hardness, Rockwell hardness is also used to understand what the hardness of material is in numerical terms. This is done through the use of a Rockwell hardness test and a Rockwell hardness scale. The exact method can be found in ASTM E18.What is the principle of Rockwell hardness test? Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method.

The Rockwell test is the less destructive alternative to the Brinell test because it uses a smaller indenter. It is the easiest and least expensive hardness test to administer because it requires very little material prep. Unlike the Brinell Hardness Test, the Rockwell Hardness Test can also be used on many kinds of hardened materials.

Rockwell Hardness Tester. The Rockwell hardness test is distinguished by its efficiency and the minimal damage it imparts on the test specimen. This test measures the depth of penetration of an indenter under a large load compared to the penetration made by a preload.

This lower cost and swiftness led the Rockwell test to become the most widely employed hardness measurement system – and this remains the case in 2021. Another advantage of Rockwell testing over Brinell hardness testing is the size of the calibration blocks which are used to regularly check that the test machines are giving accurate results.The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .DEFINITION OF THE BRINELL HARDNESS TEST The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His solution was to press a railway wheel-bearing ball into the material and then measure the size of the mark it left.

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learrn more about hardness testing basics here. The Brinell hardness test method as used to .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell . Diagram of Brinell Hardness Testing Machine. Brinell Hardness Test is one of the most important hardness tests in the engineering industry and metallurgy. It is used when the surface of the metal is very rough to use .

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; . Selection of an appropriate scale: Different testing scales (e.g., Rockwell B or C, etc.) are designed for materials of varying hardness. The test's success is largely dependent on choosing the correct scale.

disadvantages of rockwell hardness test

For instance, converting from a Rockwell hardness test on the C scale (HRC) to a Brinell hardness test value requires using the formula: BHN = 5.970 x (HRC + 104.7). This formula gives an approximate value for the Brinell hardness value, and quality assessment professionals use it to create the conversion tables and charts for instant conversion.

Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. . Common indentation hardness scales are Brinell, Rockwell and Vickers. See also: Hardness . Besides the correlation between .The easy to use hardness testing software supports the operator with single tests, as well as complex test tasks. Hardness testing according to current standards. Our DuraVision series offers a wide load range from 0.3-250 kg or from 3-3,000 kg for test methods including Vickers, Brinell, Rockwell, Knoop, plastics testing and carbon testing.Macro-Hardness (Rockwell and Brinell) testing is the most commonly applied materials test in industry due to several factors: 1) Macro-Hardness Testing is simple to perform and does not require highly skilled operators; 2) Through the use of different loads and indenters, hardness testing can be used for determining the

This article details the Brinell to Rockwell hardness conversion chart, which explains how the test results of one scale can be translated into another. . Both these scales use the ASTM standards to determine and represent the different hardness levels of metallic materials. The Brinell and Rockwell method uses diamond or steel ball indenters .

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness. Vickers hardness te.

condom leakage tester

carbonation test chamber market

O Auto Agendamento Online é uma solução desenvolvida para oferecer a você, nosso cliente, parceiro e paciente, um meio ágil e simplificado de realizar o agendamento de .

rockwell hardness test differ from the brinell test|brinell hardness test calculation